7. Various film deposition technologies and systems based on the Chemical Vapor Deposition (CVD) method

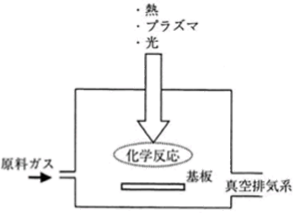

Figure 7.1 The conceptual diagram of CVD 2)

While PVD forms thin films by evaporating thin film materials directly, CVD forms thin films through chemical reactions by using the compound gases containing thin film constituting atoms as raw materials. CVD is classified into several methods depending on the source of energy used for the chemical reactions or the difference in raw material gases. Figure 7.1 shows the conceptual diagram of CVD, and Table 7.1 shows the categories according to the reaction types.

Most CVD systems use a roughing exhaust system only as a vacuum exhaust system. In addition, creating uniform gas flow is a point, because gases are used as raw materials. As there are many raw material gases that are toxic, combustible, and explosive, careful attention needs to be paid to gas introduction and exhaust gas treatment systems.

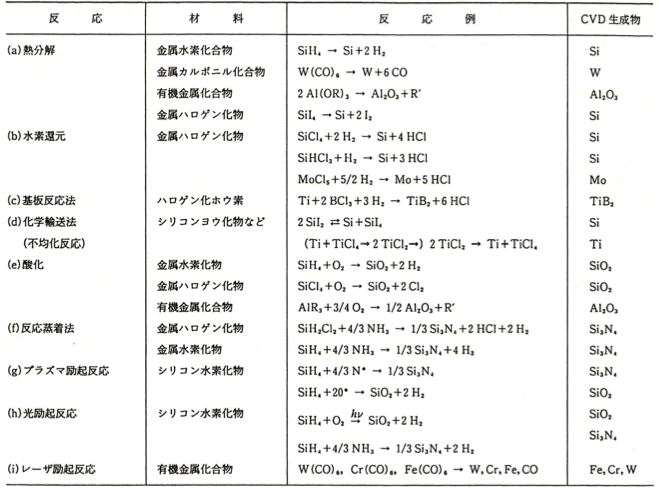

Table 7.1 The categories of the reaction types of CVD 2)

7.1 Thermal CVD (Thermal Chemical Vapor Deposition)

This method forms an intended thin film by leading raw material gases to the reaction container using a suitable carrier gas, and then causing a chemical reaction on a hot substrate surface. In general, a pressure between atmospheric pressure and several hundreds of pascals is used. The Hot Wall method that heats the whole reaction container in which a substrate is placed initially seems suitable for the formation of films on substrates with complex geometry, but the problem is that thin films also adhere to the outer wall. In addition, the Cold Wall method where a chemical reaction is caused on a substrate by decreasing the wall temperature and heating the substrate only is also used.

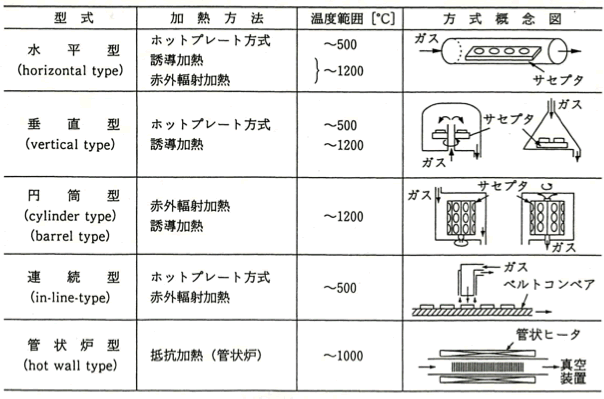

Table 7.2 Various heating methods used in thermal CVD systems 2)

7.2 Plasma CVD (Plasma-enhanced Chemical Vapor Deposition)

This method promotes a chemical reaction by turning raw material gases into a plasma state to generate active excited molecules, radicals, and ions. It is characterized by an ability to form thin films at a substrate temperature lower than that of the thermal CVD method, and a pressure of approximately between 100 and 1 Pa is used.

Table 7.3 shows the plasma generation methods.

Table 7.3 The plasma generation methods used in CVD 3)

7.3 Photo-CVD (Photo-Chemical Vapor Deposition)

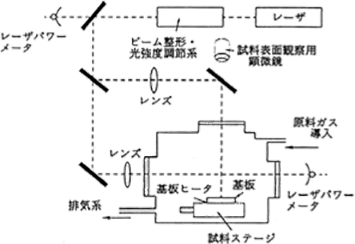

This CVD method uses light as energy for chemical reactions, and various types of electric discharge tubes and laser are used as light sources. If light in the infrared region is used, a thermal reaction would mainly be used. On the other hand, if specific molecules are excited by light or if active species generated through bond dissociation are used for the reactions, photon energy equivalent to the chemical bond energy is necessary and a light source in the ultraviolet region is used. In such a case, films can be formed at low temperatures. Figure 7.2 shows an example of a Photo-CVD system configuration.

Figure 7.2 An example of a photo-CVD system configuration 2)

7.4 MOCVD (Metal Organic Chemical Vapor Deposition)

This CVD method uses organic metallic compounds with a metal-carbon bond as raw materials. It is mainly used in the formation of III-V and II-VI compound semiconductor thin films.

7.5 ALD (Atomic Layer Deposition)

In the ALD method, raw material molecules adsorb onto a surface, and the surface chemical reaction is suspended autonomously after a layer is formed. Then, different kinds of raw materials are supplied to form an intended substance, and at the same time, the suspended chemical reaction is resumed. In this process, a layer of the intended substance is formed. By repeating this process, thin films can be formed intermittently layer by layer at the atomic level. This is characteristic of this method.