Electronics and electricity

Electronics and electricity

High frequency filters

For transmitting and receiving radio waves of mobile communication devices as typified by cellular phones, RF filters using Surface Acoustic Waves (SAWs) and Bulk Acoustic Waves (BAWs) are employed.

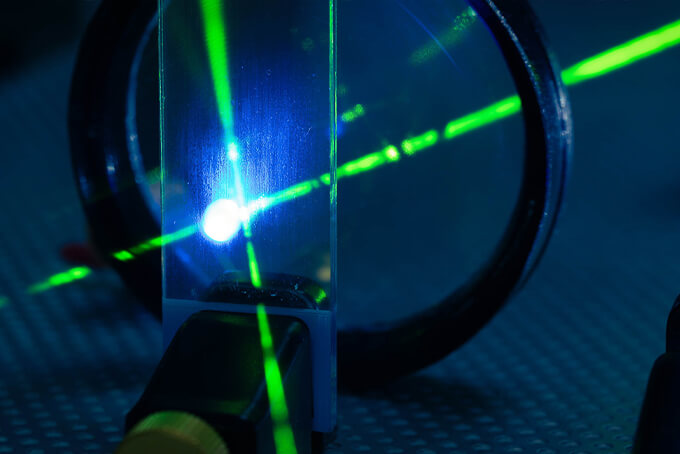

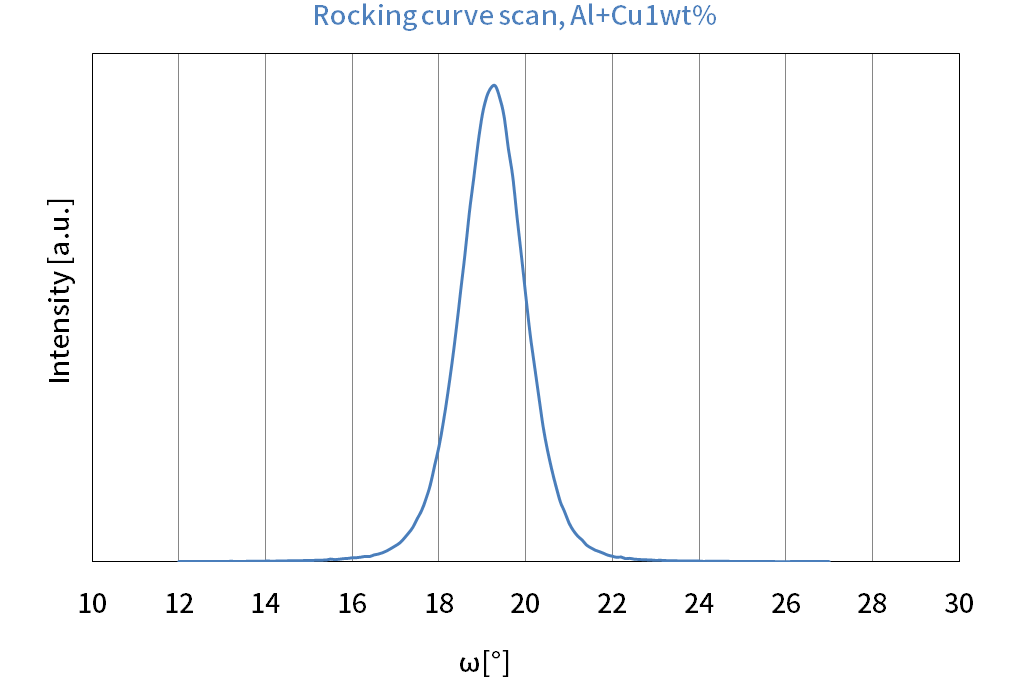

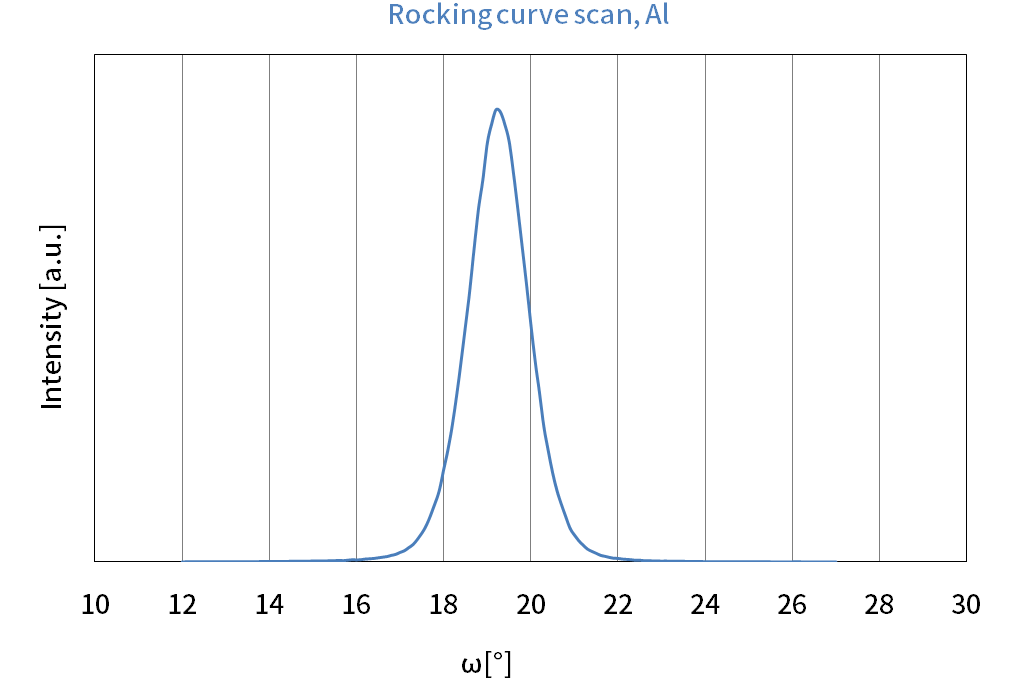

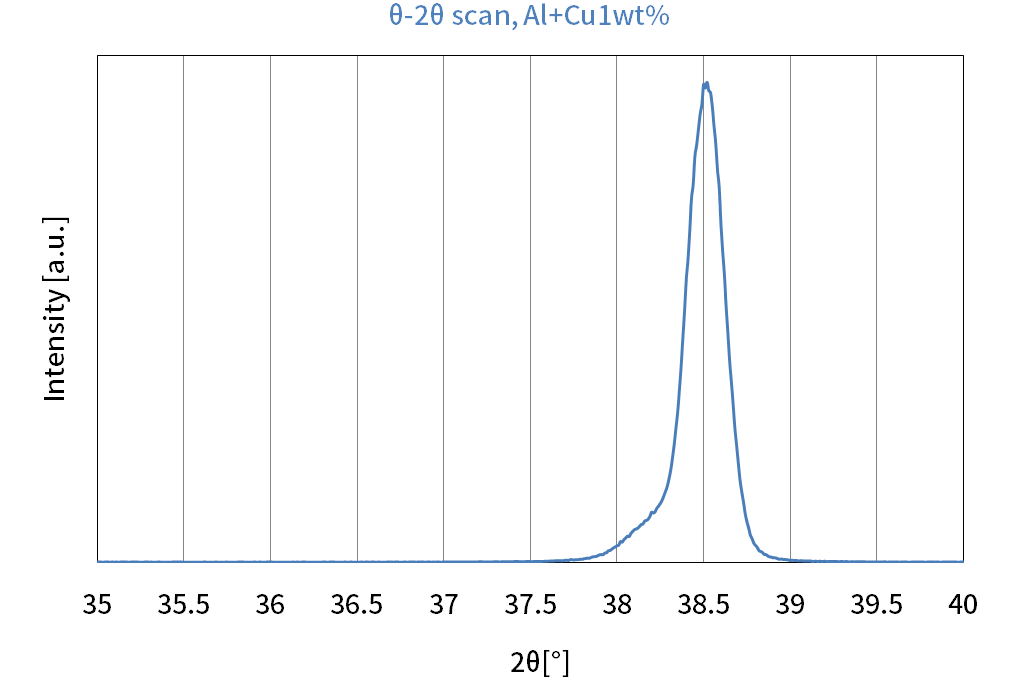

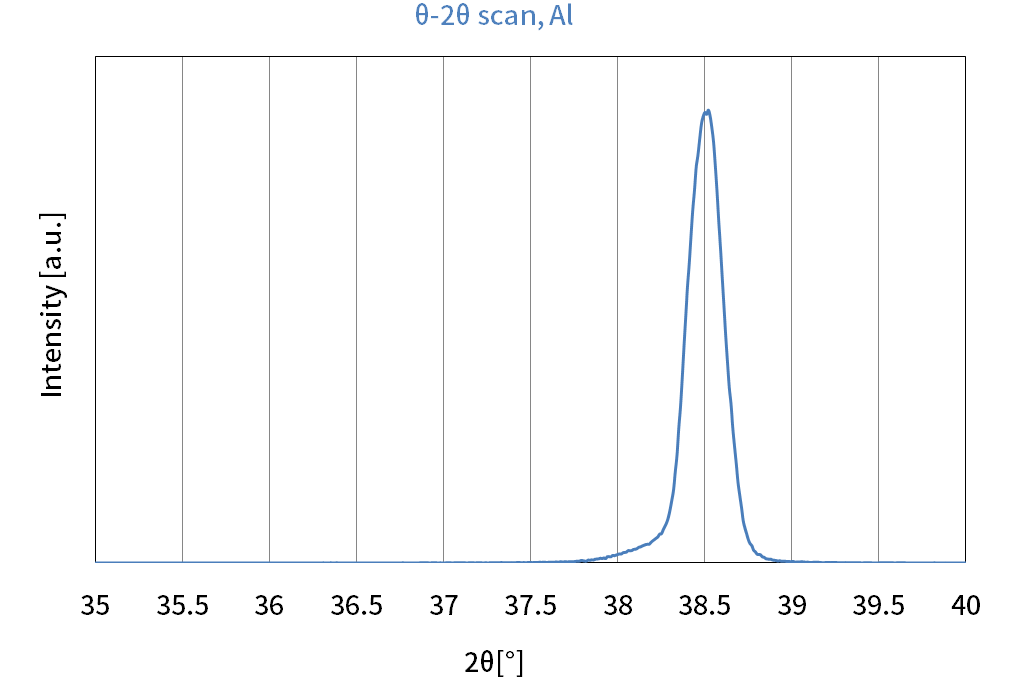

Orientation of Al and AlCu films

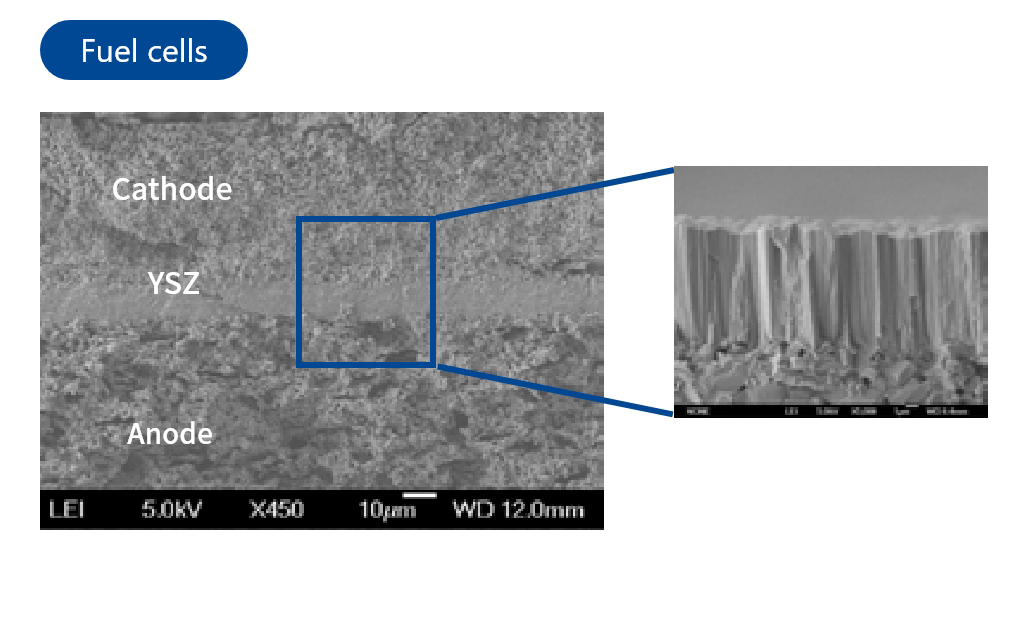

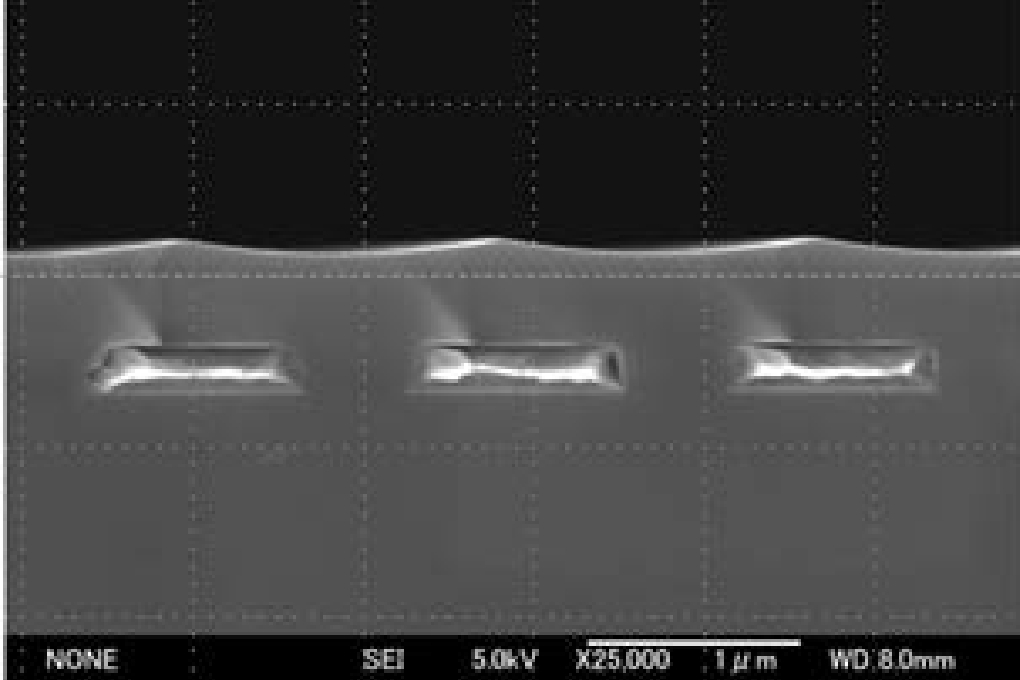

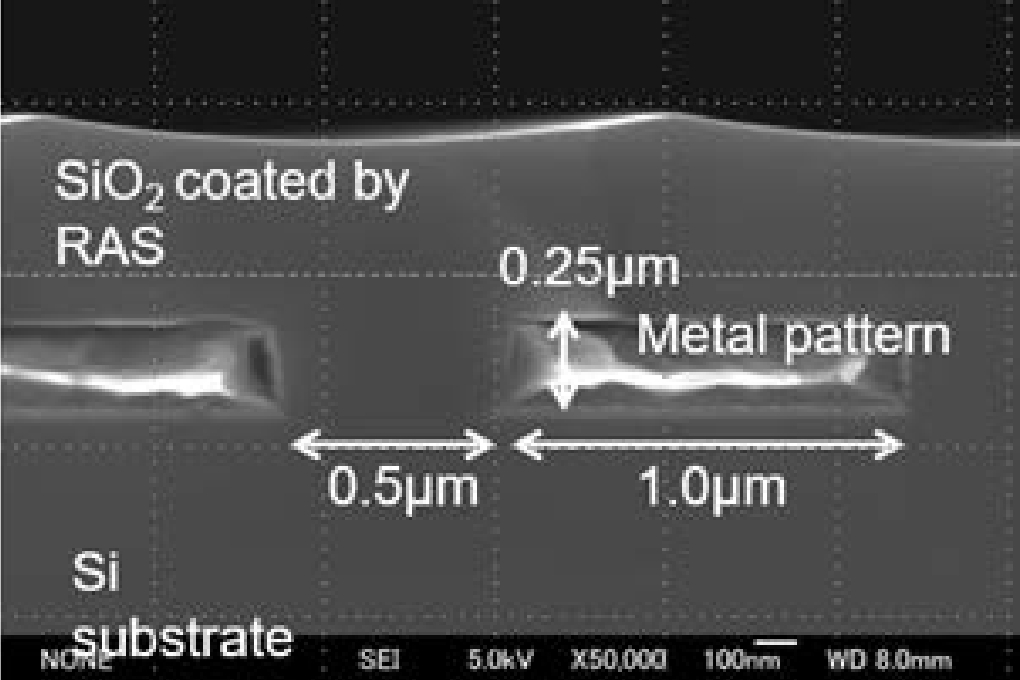

Cross-sectional SEM images of a TC-SAW filter (Cooperation: Professor Hashimoto of Chiba University)

SAW filters, made with comb-shaped electrodes called IDTs (Interdigital Transducers) formed on piezoelectric substrate surfaces, form the bandwidths of RF filters using the resonance characteristics of surface acoustic waves excited by IDTs.

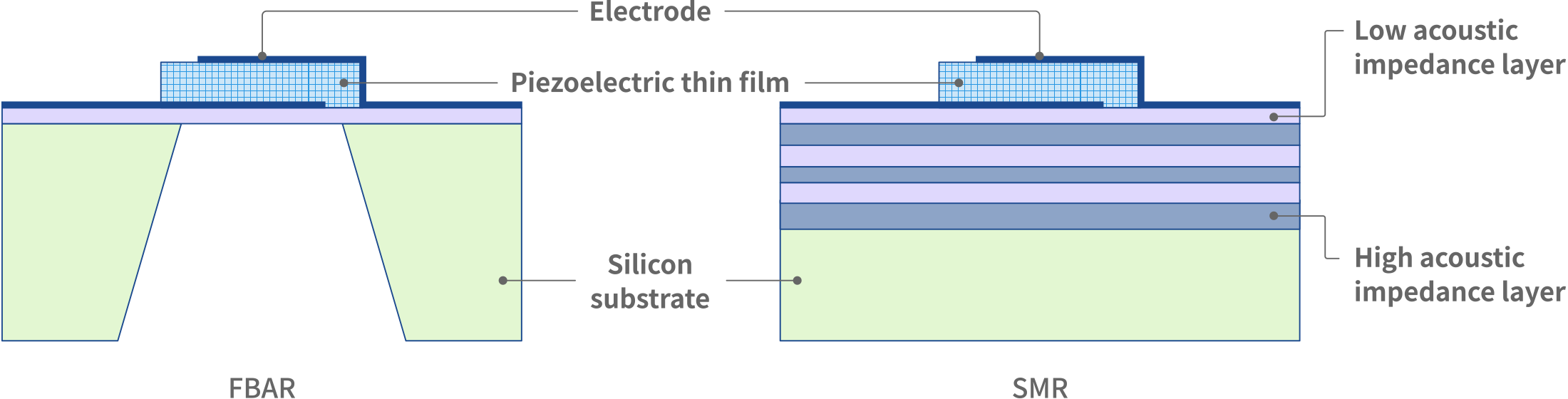

The technology for higher frequencies is RF filters that utilize Bulk Acoustic Waves (BAWs).

BAW type filters are made with a piezoelectric body placed between upper and lower electrodes and utilize thickness extensional vibrations.

RF filters utilizing the resonance of BAWs enable superior filter characteristics with high steepness to be obtained.

BAW devices can be classified into FBARs (Film Bulk Acoustic Resonators) and SMRs (Solidly-Mounted Resonators).

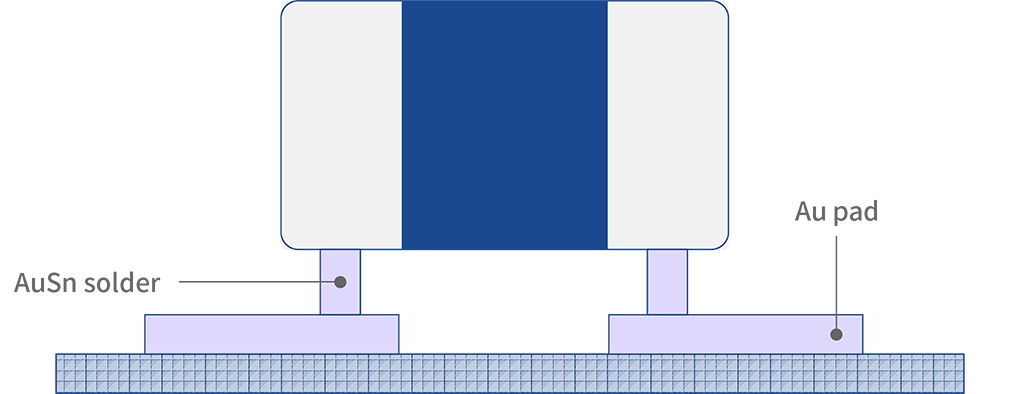

Formation of metallic electrodes

It is possible to form electrode films with desired functions, according to the types and characteristics of the metallic substance materials. Metals such as Au, Al, Cu, and Ti are used as the pad electrodes for the passive/active elements in electronic components, and the contact resistances of wirings for such metals and elements can be minimized.

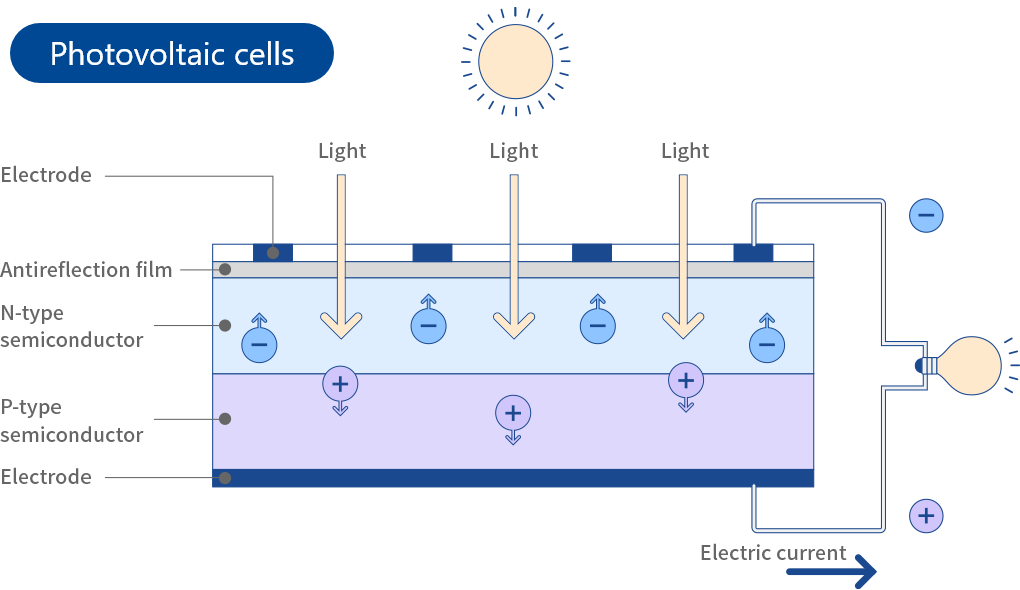

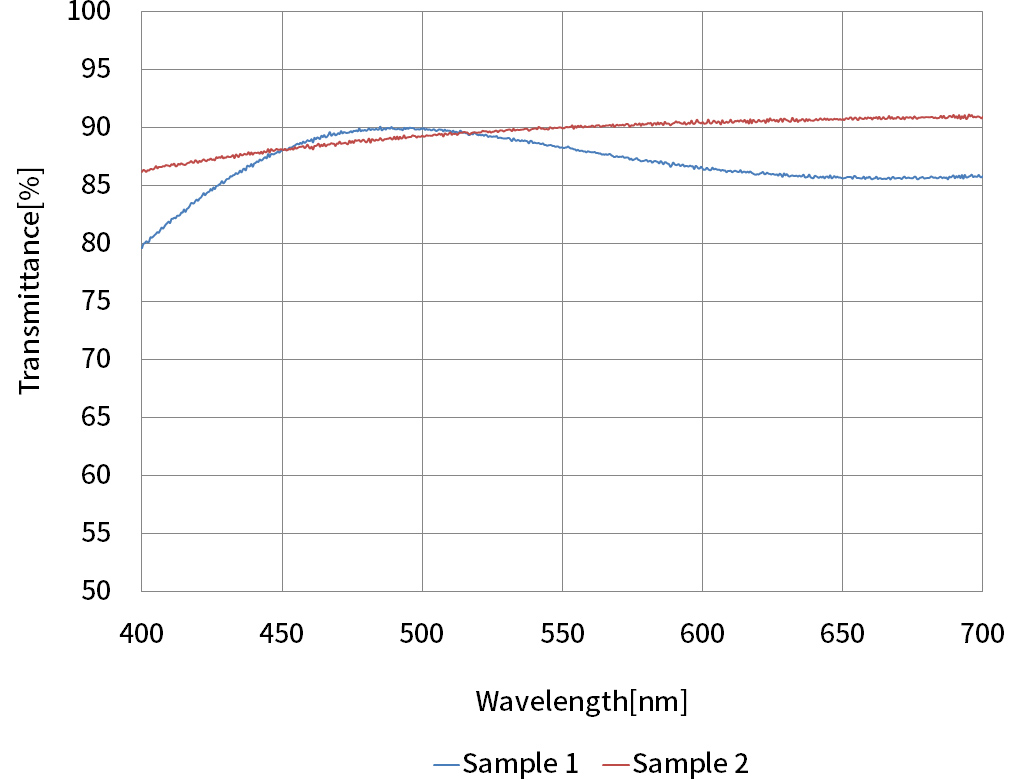

Formation of transparent electrodes

Transparent conductive films meet both the demands of conducting electricity and obtaining transparency to achieve the passage of light. These films, made of ITO that is a mixture of indium oxide and tin oxide (therefore, they are also called “ITO films”), realize a wide variety of functions such as “static discharge prevention” and “transparent electrodes” for touch-screen displays and “transparent electrodes” for the next-generation photovoltaic cells. They are also employed in transparent heaters that prevent dew condensation and snow accretion.

| Experiment No. | Sample 1 | Sample 2 |

|---|---|---|

| Resistance value [Ω] | 2.03 | 24.7 |

| Sheet resistance [Ω/□] | 9.09 | 110.61 |

| Film thickness [nm] | 145.9 | 16.4 |

| Specific resistance [Ω・cm] | 1.33E-04 | 1.81E-04 |

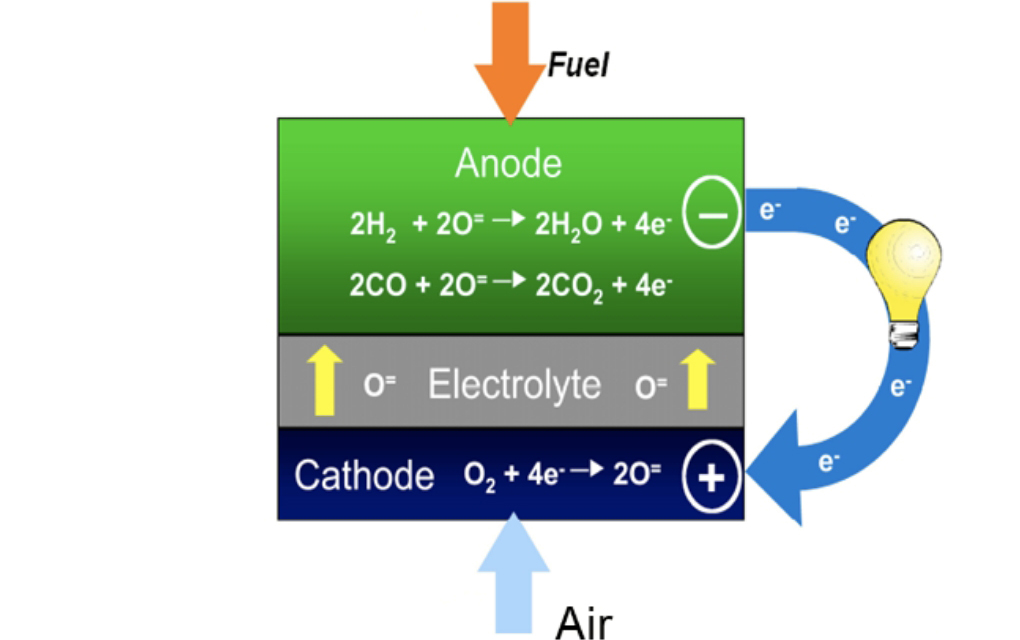

Next-generation energy

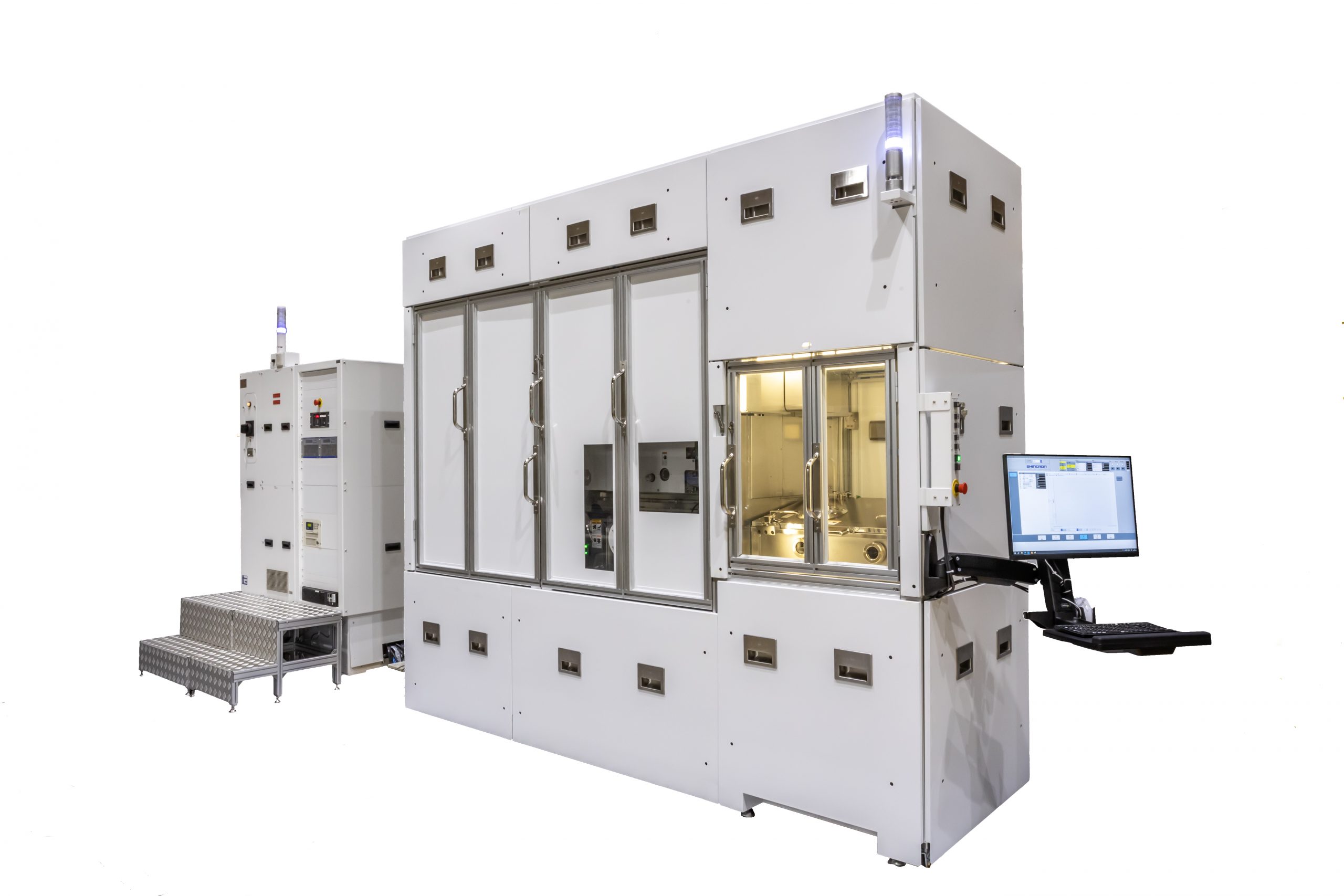

Thin film technology holds the key to further advancement in fuel cell performance, which extracts electricity from chemical energy generated through the reaction of a fuel such as hydrogen with oxygen, as well as all-solid-state batteries in which electrolyte is solidified. Shincron offers a wide variety of solutions ranging from material search to mass production.